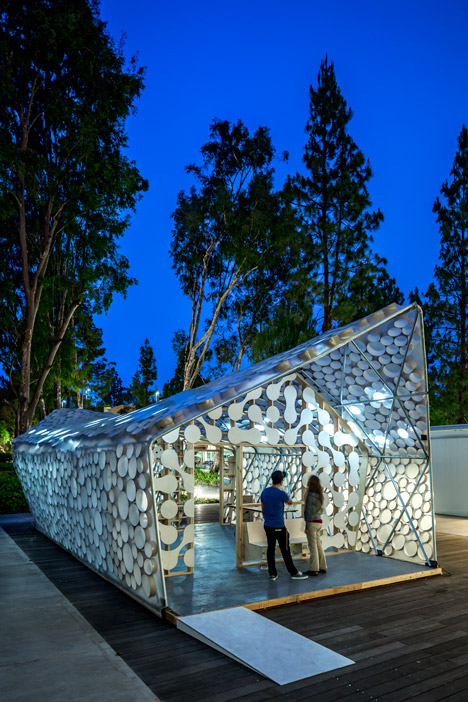

Students and faculty members at University of California, Los Angeles (UCLA) have developed a small house to assist deal with the city’s low-cost housing shortage.

Encompassing 500 square feet (46 square metres), the Backyard BI(h)OME is created to incorporate a bedroom, living space, bathroom, kitchen and dining room. The little property is meant to be erected in a homeowner’s backyard, exactly where it can be rented out or occupied by family members.

“The minimal-value, reduced-affect BI(h)OME could serve as housing for an elderly mother or father, a returning school graduate, or a rental unit,” explained the college.

“Rather than requiring a mortgage loan, it could be leased, like a auto, so it is semi-permanent, can flexibly serve the demands of house owners for as prolonged as they want, and then be recycled or reinstalled.”

The prototype was developed by college students and faculty at CityLAB, a believe tank inside of UCLA’s architecture and urban style division that explores concerns connected to urbanism, sustainability and infrastructure.

The idea was partly driven by the LA mayor’s contact for a hundred,000 new residential units to be developed by 2021. The city is amid the least-inexpensive housing markets in the US, in accordance to reviews.

Nearly 500,000 single-loved ones properties sit within the city’s boundaries, and erecting so-referred to as “accessory dwellings” in the gardens of 20 per cent of those homes would meet the mayor’s goal, according to the school.

Relevant stories: see much more micro homes

“A single of the region’s housing options lies in our own back yards,” said the college.

The designers also intend for the dwelling to attract animals. 1 wall can be transformed into an edible garden, and modular units can be extra to give homes for bats or birds.

The construction is composed of a steel pipe frame and a shear wall manufactured of timber. The exterior is clad in a “remarkably sound nevertheless light” skin composed of two translucent layers of ETFE, a variety of fluorine-based plastic. Sandwiched amongst the layers is a honeycomb formation of paper cylinders.

Photovoltaic cells can be printed onto the outdoors layer of the building envelope, whilst LED lights can be integrated into the inner layer.

The property is developed to be mounted to a gabion-fashion basis, with posts screwed immediately into the ground. Due to the fact it consists of a composting toilet, the dwelling requires no sewer hookup. Water is provided through a standard hose.

The residence is each easy to set up and eliminate, the college explained, and can be configured in myriad approaches to fit any backyard.

“The environmental impact of the framework above its whole life cycle is in between 10 and one hundred occasions much less than a typical auxiliary dwelling,” said the college. “The BI(h)OME demonstrates – in its design and style, fabrication, occupation and recycling – what sustainability means at a individual degree.”

Other current styles for micro-homes include mobile dwellings that would move all around on Polish railway tracks and a three-metre-broad unit that rests on stilts in Hohenecken, Germany.

Photography is by Nico Marques/Photekt.

Project credits:

Concept development and executive producer: cityLAB – UCLA, Dana Cuff, Jonathan Crisman, Carla Salehian, Per-Johan Dahl

Architect: Kevin Daly Architects, Kevin Daly, Peter Nguyen

Structural engineer: Workpoint Engineering, Ben Varela

Industrial design: Kody Kellogg

Landscape design and style: Therese Kelly

Biodiversity and habitat: Jon Christensen, UCLA Inst of the Environment and Sustainability Ursula Heise, English

AUD Student Staff: Andrew Akins, Garth Britzman, Dee Chang, Katie Chu, Ciro Dimson, Adrien Forney, Kara Moore, Dami Olufoweshe, Lyo Liu, Trenman Yao, Sarah Sibohan Johnson, Mark Lagola, Nawid Piracha

Undertaking fabricators: Julian Daly and Max Miller

Custom carpentry and woodwork: CA Development, Carlos Grande

Envelope: Shrink Wrap Pros, Craig Keys

AUD fabrication Manager: Philip Soderlind

UCLA services management team: Leroy Sisneros, Coordinator, Erik Ulstrup

Pipe bending team: Blake Rainy, Carlos Rigual

Metal fabrication: Lorenzo Villanueva

Structural diagram

Structural diagram  Area layout

Area layout  Floor program Dezeen

Floor program Dezeen