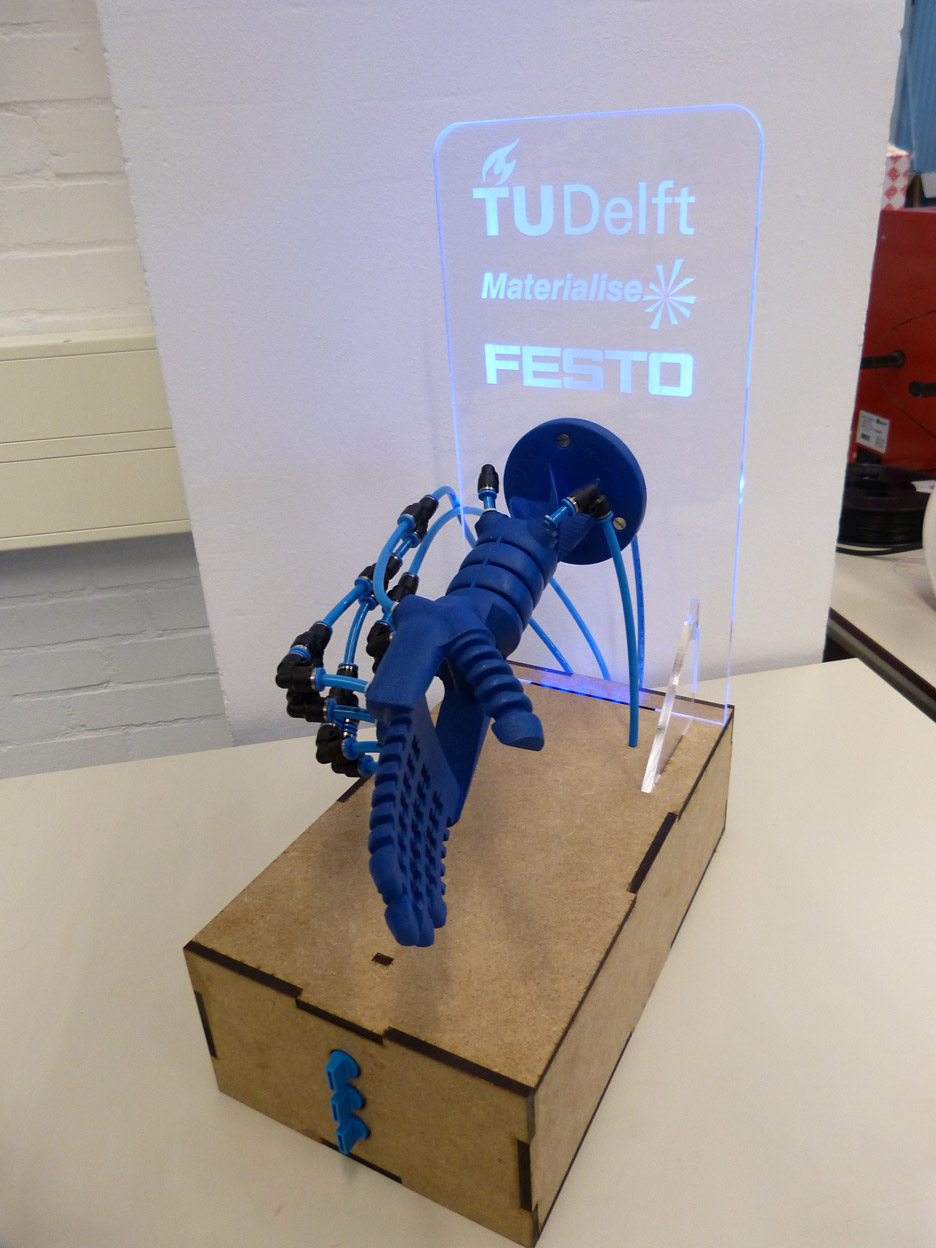

Dutch Style Week 2015: Delft University of Technologies graduate Rob Scharff has created a soft robotic limb that can shake hands with folks.

The hand was created as component of Scharff’s Soft Robotics analysis venture – which focuses on the approaches robots can be integrated with more tactile resources, and so improve robot-human interactions.

Video displaying a demonstration of Rob Scharff’s Soft Robotics 3D-printed hand

“Robots are turning out to be omnipresent in our lives,” Scharff advised Dezeen. “This helps make it quite exciting and important to think about robotics from a layout perspective.”

“At the moment, most robots are reasonably rigid machines which make unnatural movements. Soft robotics – the application of soft components in robotics – gives a various point of view to interacting with robots,” he additional.

Scharff referenced all-natural biological systems to design the hand, including human muscle groups and the structure of an elephant’s trunk.

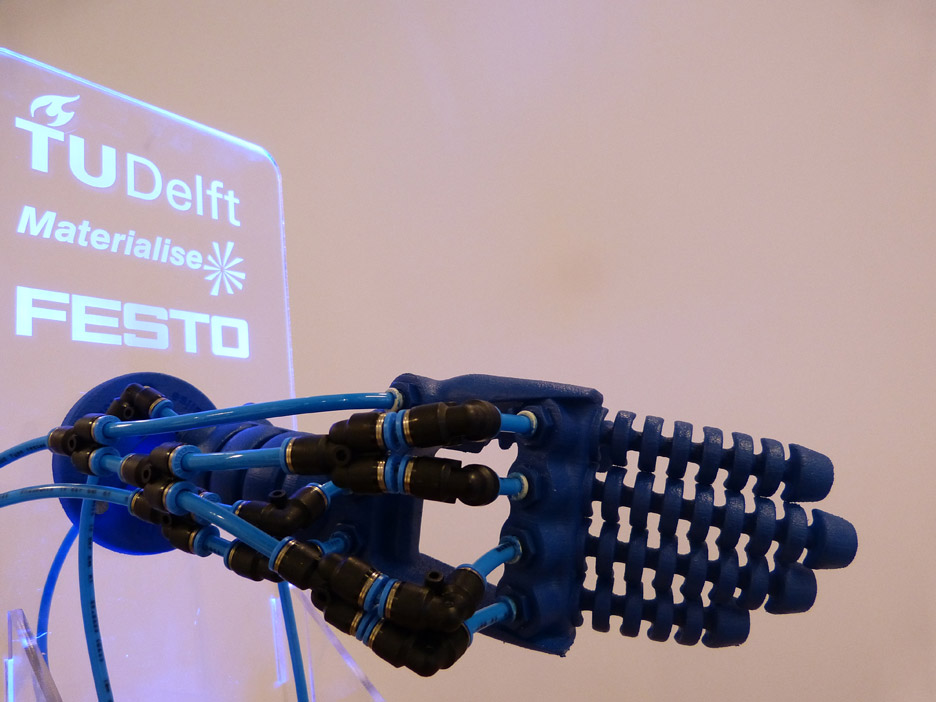

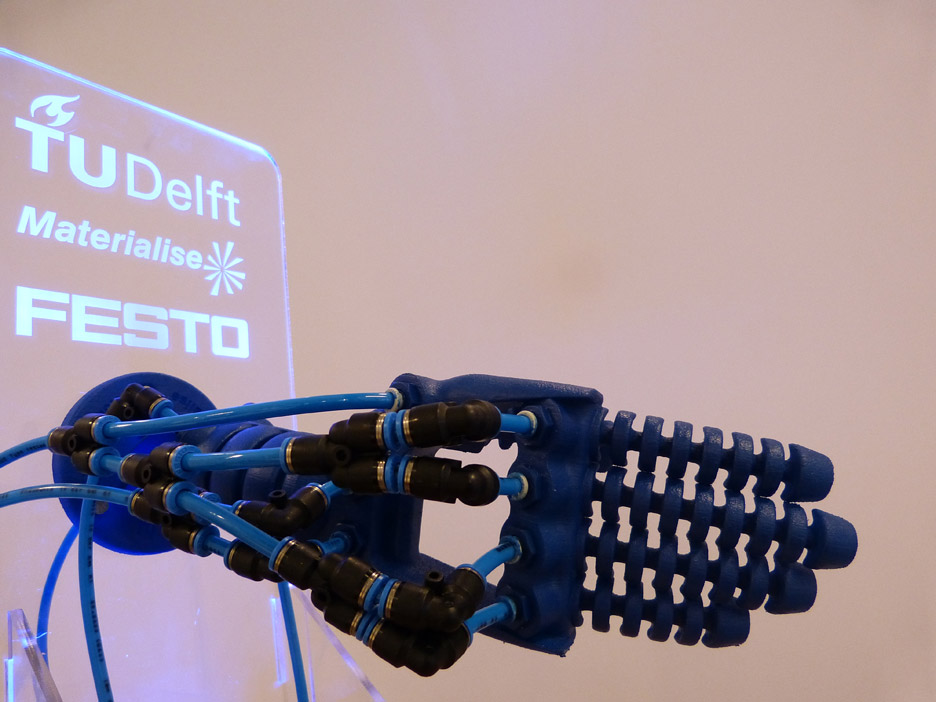

The palm of the hand includes integrated air chambers, which perform like bellows, and reply to the pressure applied when held by a human hand.

Associated story: 3D-printed Robohand assists young children born without having fingers

Squeezing the robotic limb, in a handshake for example, benefits in an enhance in air pressure in the chambers, which causes the fingers to grip a lot more or significantly less, based on how company the original handshake was.

“This shaking of hands is utilised as a metaphor to demonstrate how the technology can be utilised to boost human-robot interaction,” said Scharff.

“The engineering can be applied in for example orthotics, prosthetics, care robots, exploratory robots and industrial grippers.”

The fingers and thumb of the hand can also be separately controlled, utilizing pneumatics, and the wrist can rotate in the two directions.

The hand was printed as a single piece using selective laser sintering (SLS) – a printing strategy that melts powder employing a laser to kind the form of a product – utilizing a versatile material comparable to polyurethane.

Though at present nonetheless a prototype, Scharff is continuing to develop the engineering for use in 3D-printed custom-fit gloves, which could assist men and women discover to grip objects once more.

The hand was on demonstrate as component of the Thoughts The Phase exhibition in Eindhoven’s Klokgebouw constructing for Dutch Design and style Week 2015, which runs from 17 to 25 October.

The 2015 James Dyson Uk Award was provided to startup Open Bionics’ robot hand, which was similarly 3D-printed, and designed as a low-cost option to present prosthetics.