Graduate exhibits 2015: Royal School of Art graduate YunTing Lin has produced a new material from plant fibres and naturally fermented cellulose, and used it to produce a storage method and speakers .

Storage technique

Storage technique

Nanocellulose Fibreboard is a non-toxic, one hundred per cent recyclable and 100 per cent biodegradable material made from a composite of plant fibres, such as flax, bound together using nanocellulose – a fibrous substance created by bacterial fermentation.

Storage technique

Storage technique

The two materials are mixed with water and then compress-moulded into the needed form.

“Eco-pleasant material isn’t going to need to have to be dull – it can be desirable,” explained the Taiwanese designer.

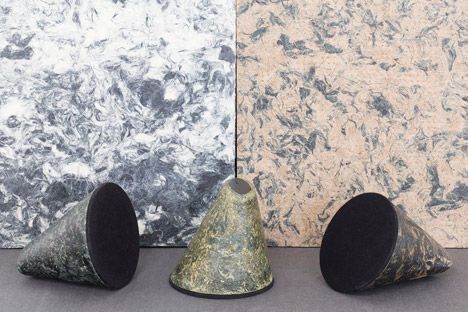

Bluetooth speakers

Bluetooth speakers

Bacteria and other microbes like yeast and algae are more and more currently being employed to expand resources. Designers this kind of as Suzanne Lee have utilised microbes to make kinds of fabric in vats of liquid, which she turned into objects of clothing, while a biologist and a designer are currently developing a bacteria and yeast “micro-factory” to be utilized at property.

Connected story: Growduce “micro-factory” idea would permit users to grow their very own goods

Lin created three merchandise to show the potential of his material: an interior construction panel, a modular storage method and Bluetooth speaker.

Bluetooth speakers

Bluetooth speakers

“There are so several new sustainable resources out there, but occasionally they do not seem desirable, so I started to wonder about the likelihood of getting a materials that could be eco-pleasant, beautiful and very easily accessible,” he explained.

Bluetooth speakers

Bluetooth speakers

The ability to vary the density of Lin’s materials enables the production of a low-density version with acoustic and thermal insulation properties, which make it appropriate for interior building.

Construction panels

Construction panels

Coloured fibres can be used to control the final hue of the interior panels, with no the need to paint their surface or add additional materials. Alongside interior building panels, furniture is one particular of the most frequent uses for fibreboard products.

Development panels

Development panels

Looking for to demonstrate his material’s possible to replace fibreboard, Lin developed and made a modular storage program comprising single box units jointed with each other with dowels that enable free of charge rotation.

Relevant story: Mushroom-primarily based modelling kit makes it possible for end users to develop their personal designs

“Its sustainable manufacturing and recyclability could transform the environmental issues that existing fibreboard leads to,” mentioned Lin, who studied on the RCA’s Design and style Products course. “Unlike MDF and chipboard, which demand a laminated skin for decoration, Nanocellulose Fibreboard functions a versatile pattern.”

Building panels

Building panels

Finally, cone-shaped compress-moulded Bluetooth speakers illustrate the material’s likely to exchange moulded plastic whilst demonstrating its acoustic properties.

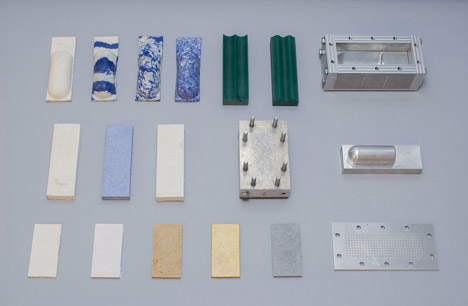

Nanocelluose Fibreboard moulded materials samples

Nanocelluose Fibreboard moulded materials samples

“The manufacturing method demands much less power than creating plastic, for that reason I think Nanocellulose Fibreboard could be extensively employed as a casing material for customer electronic items,” stated the designer.

Materials sample

Materials sample

The US consumes in excess of 500 million square metres of MDF and particle-board each and every year.

Lin’s new material aims to overcome problems related with MDF, such as a reliance on wood, the inability to recycle it, and the release of urea-formaldehyde from the resin used to bind the fibres, which has been linked with cancer.

Near-up of a coloured materials sample

Near-up of a coloured materials sample

As it uses related manufacturing approach to MDF, Nanocellulose Fibreboard could be developed in existing MDF factories with a handful of easy alterations to the machines, according to Lin.

Material samples and mould components

Material samples and mould components

The undertaking is getting presented at the RCA’s graduate present in London. Demonstrate RCA 2015, which runs right up until 5 July, also functions a spiral staircase that straps to any tree trunk and a “energy glove” that can be employed to sculpt hard materials like stone and wood by hand.