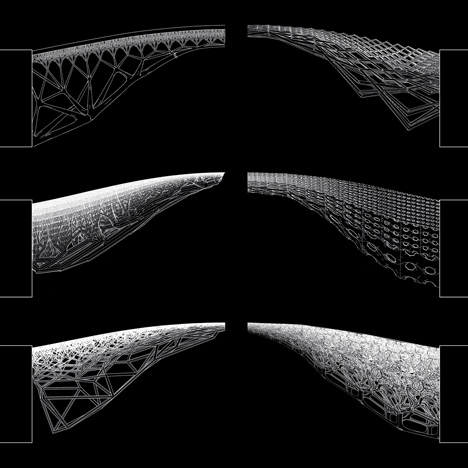

Dutch designer Joris Laarman has created a steel bridge that will be 3D-printed by robots .

The ornate metal structure, which will span a canal in Amsterdam, will be printed in-situ by robotic arms. The place of the bridge will be announced quickly, and completion is set for 2017.

The versatile 6-axis robots – which are in a position to rotate their arm along 6 distinct planes of movement – will print a load-bearing structure that will assistance their own weight, allowing them to commence on one particular financial institution and work their way across to the other side, printing steel as they go.

“This bridge will display how 3D printing finally enters the globe of huge-scale, practical objects and sustainable materials while enabling unprecedented freedom of type,” stated Laarman. “The symbolism of the bridge is a beautiful metaphor to connect the engineering of the future with the outdated city, in a way that brings out the very best of each worlds.”

The task has been produced by MX3D, a engineering startup launched by Joris Laarman Lab to investigate techniques of printing massive, sophisticated structures.

It builds on technological innovation created by Jaarman that makes it possible for industrial robots to “draw” metal structures in the air. This potentially allows far more substantial structures to be printed than are currently feasible.

Related story: British architect claims “initial architectural application” of 3D printing

“What distinguishes our engineering from traditional 3D printing techniques is that we operate in accordance to the ‘printing outdoors the box’ principle,” mentioned Tim Geurtjens, chief technology officer at MX3D.

“By printing with six-axis industrial robots, we are no longer restricted to a square box in which every little thing transpires,” Geurtjens additional. “Printing a functional, existence-dimension bridge is of program the ideal way to showcase the countless prospects of this approach.”

The task, which is supported by design software program business Autodesk and building organization Heijmans, could sooner or later let entire buildings to be printed.

“The MX3D platform is a prospective game changer,” stated Maurice Conti, director of strategic innovation at Autodesk. “Breaking totally free of the conventional limitations of additive manufacturing – small-size prints and bad material efficiency – this engineering opens up choices for architectural-scale, fairly low-expense, metal structures that are as complicated as the designer’s imagination.”

Connected story: 3D-printed buildings to become reality “in the not-as well-distant potential”

Other recent explorations of architectural-scale 3D printing include Foster + Partners’ concrete-printing robot and Arup’s experiments with printed developing parts.

Laarman is a pioneering designer who works at the interface among technological innovation and classic object-producing. Tasks by the 35-yr-0ld include 3D-printed metal chairs and explorations in making furnishings based mostly on the way bones increase.