Dutch Style Week 2015: designer Troy Nachtigall has utilized scans of feet to generate a pair of 3D-printed shoes, which he claims are more comfy than typically manufactured footwear .

Nachtigall, along with style designer Pauline van Dongen and industrial designer Leonie Tenthof van Noorden, had been commissioned by Dutch minister of training, innovation and science, Jet Bussemaker, to produce an outfit for her to wear at the Netherlands’ Spending budget Day.

Given the active nature of the event, Nachtigall’s style had to be comfortable ample to put on throughout the complete day, while demonstrating the future of footwear and vogue.

To obtain this, the team set about producing a pair of footwear that were totally modelled on the minister’s feet, and tailored to her day-to-day behaviour.

“We commenced with a 3D physique scan of the minister from three diverse perspectives so we could see what it would look like when she was strolling,” Troy Nachtigall advised Dezeen. “We analysed her foot quite closely and came up with a pair of shoes produced up of flexible filaments”.

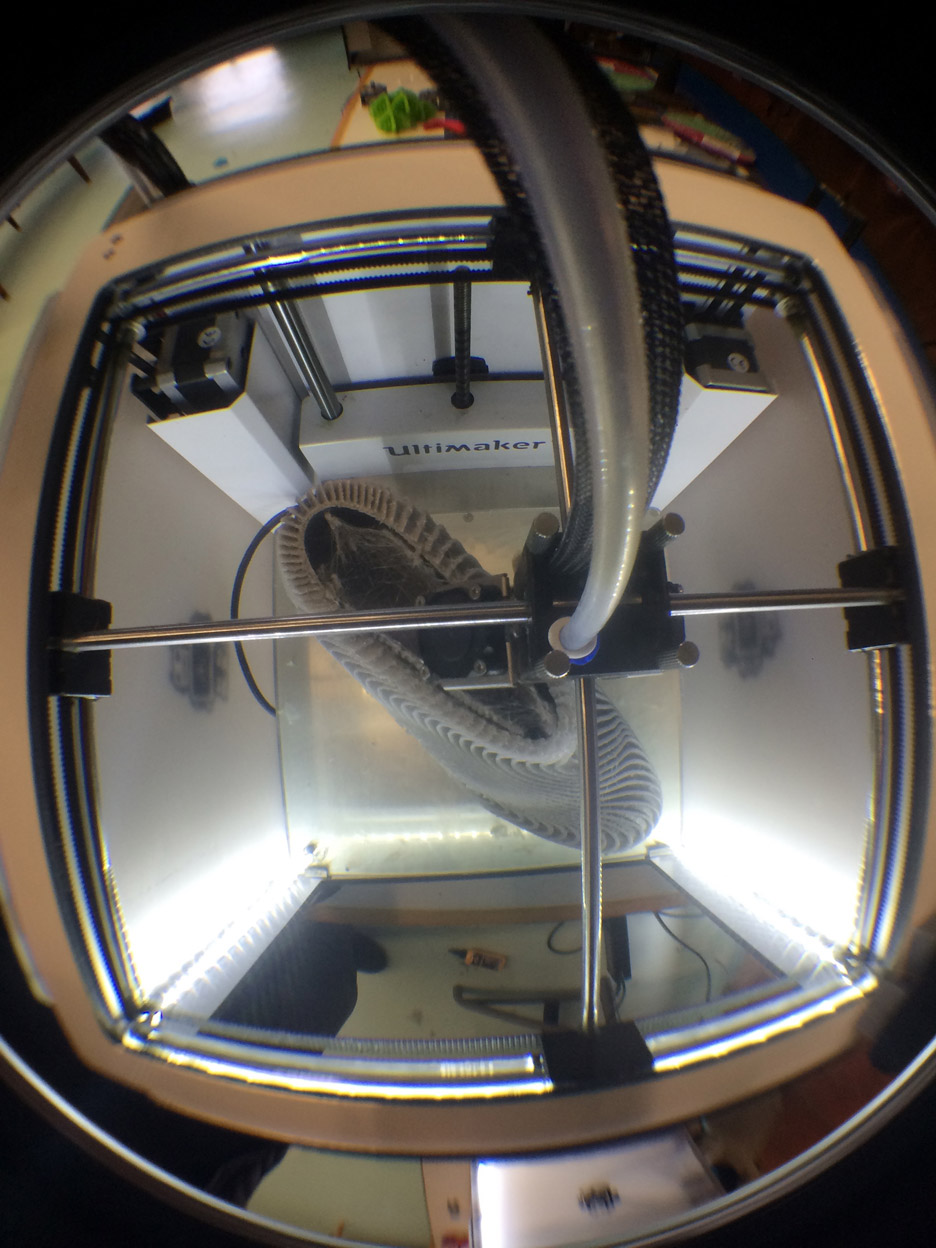

Constructed fully from Filaflex – a filament materials produced by Spanish 3D-printing company Recreus – the shoes took one hundred hours in complete to print, and are produced up of a series of soft, vertical curving lines that move to enhance versatility.

Associated story: Adidas generates 3D-printed Futurecraft soles to mimic runners’ footprints

“Using the algorithms that Leonie came up with, we invented a shoe that is stable the place it demands to be stable, and soft the place it demands to be soft,” stated Nachtigall. “They’re cozy, and comfortability was our major aim.”

After examining earlier 3D-printed footwear patterns, the designer opted for a softer material that would supply the comfort of organic fabrics and prevent the shoes from rubbing.

“As far as we can inform, no one has produced a pair of relaxed 3D-printed footwear prior to,” Nachtigall said. “Pauline van Dongen with Freedom of Creation manufactured an wonderful pair of substantial heels that had been 3D-printed back in 2008 or 2009, but right after about 4 or 5 hrs of wear would commence offering you blisters. So we required a softer material that could behave more like leather, or the canvas that we wear right now.”

Along with the foot scans, the staff also took into account what the consumer would be carrying out throughout a common day in order to decide the shoe’s “behavioural fit”.

“Every single time we make a pair of shoes for a man or woman, we inquire a lot of inquiries about who they are, what they do, and what they are going to do with these footwear,” Nachtigall stated. “We’re calling it behavioural match, since it’s about how the sneakers fit, and how they behave.”

Relevant story: Francis Bitonti 3D-prints gold-plated Mutatio sneakers for United Nude

“Past just being more cozy than a normal pair of footwear, the footwear are produced from a single contemporary materials, which is a far more recyclable alternative,” he additional.

The sneakers had been manufactured by Dutch technological innovation company SLEM, and are on demonstrate at its 3D-printed footwear exhibition during Dutch Layout Week in Eindhoven from 17 to 25 October.

Other patterns on display integrated a idea auto created from reflective cuboids, and a assortment of downloadable do-it-your self clothes.

Not too long ago, Adidas unveiled a 3D-printed shoe sole that can be tailored to the exact contours of the wearer’s feet, whilst Dutch footwear brand United Nude created a pair of shoes with eight-inch-high 3D-printed heels.