Neri Oxman and her crew at MIT Media Lab have 3D-printed a collection of versions using molten glass to demonstrate layout and architectural applications for the approach (+ film).

The Mediated Matter group at the Massachusetts Institute of Technology developed a machine that extrudes the glass in its liquid form and builds it up in layers, like a 3D printer.

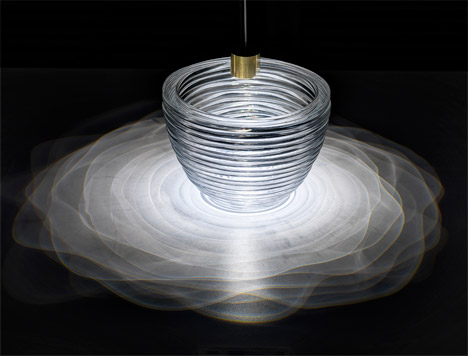

The venture, titled G3DP: Additive Manufacturing of Optically Transparent Glass, resulted in a series of vessel-like structures.

Molten glass is used as a filament, inserted into the prime of the machine and then extruded at a really higher temperature as a thin strand.

Associated story: Neri Oxman 3D prints “photosynthetic wearable” to host living organisms

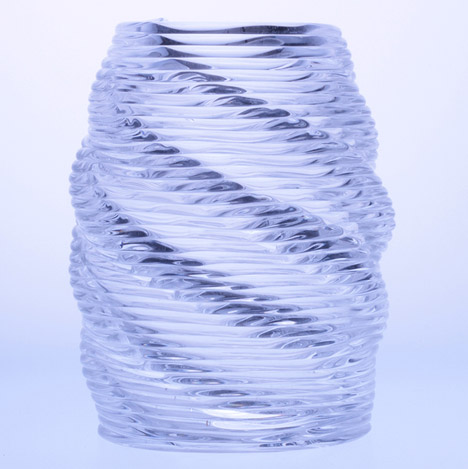

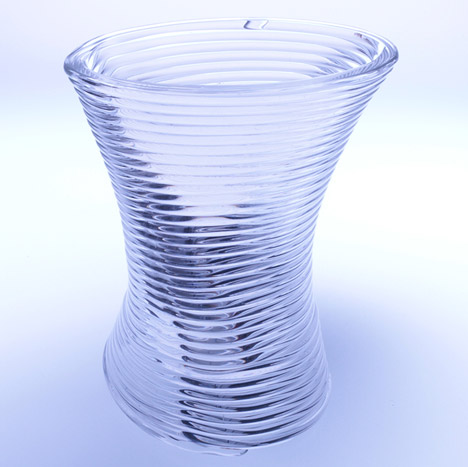

Shapes are created up in a continuous spiral of layers. The sections below cool and solidify swiftly adequate to support the sizzling viscous material laid on top.

The extruder can be programmed to apply every of these layers in a slightly different form, resulting in sculptural ribbed varieties.

It can also lay down the glass in more difficult patterns to develop types that appear as if they have been woven from the transparent materials.

“The additive manufacturing of glass enables us to produce structures that are geometrically customisable and optically tunable with substantial spatial resolution in manufacturing,” designer and researcher Oxman advised Dezeen.

The machine has two compartments, with the upper chamber acting as a kiln while the reduced chamber offers an area for the structures to anneal.

The “kiln cartridge” operates over one,000 degrees Celsius and can contain enough molten glass poured into its prime to construct a single component.

A nozzle produced from alumina zirconia silica – a chemical compound that is resistant to heat – is employed to funnel the material onto a platform.

The venture follows on from the Mediated Matter group’s 3D-printed “wearable skins”, developed to facilitate synthetic biological processes. Earlier this yr, the crew filled one of the structures’ hollow tubes with a luminescent liquid to signify how it could host photosynthetic organisms.

Oxman said that the new glass-printing technologies could permit a comparable thought to take place at an architectural scale: “Our prior operate explored photosynthetic wearable skins and in this task we desired to check out the possibility of generating architectural creating skins that are at as soon as structurally sound, environmentally informed and have the possible to incorporate and flow media via them.”

Connected stories: see much more glass style

By integrating colour into the procedure, the crew believes that the structures could restrict or handle light transmission, reflection and refraction.

“We’ve also experimented with colour gradients and are presently taking into consideration methods in which colouration may influence environmental performance, particularly solar radiation,” mentioned Oxman. “Due to the fact we can style and print outer and inner surface textures independently (not like glass blowing) we can control solar transmittance.”

Her record of likely applications for the technological innovation contains “aerodynamic building facades optimised for solar acquire” and “geometrically customised and variable thickness lighting gadgets”.

“Feel Centre Pompidou with out practical or formal partitions,” Oxman said. “Instead, take into account a single transparent developing skin that can integrate multiple functions and can be shaped to tune its overall performance.”

The G3DP project was created as a collaboration in between the Mediated Matter group at the MIT Media Lab, the Mechanical Engineering Department, the MIT Glass Lab and Wyss Institute.

Researchers contain John Klein, Michael Stern, Markus Kayser, Chikara Inamura, Giorgia Franchin, Shreya Dave, James Weaver, Peter Houk and professor Neri Oxman.