Dutch Design Week 2015: the world’s initial 3D-printed bridge in Amsterdam uses a strategy that designer Joris Laarman says could soon be utilized to create “infinitely huge structures” (+ interview).

The pedestrian bridge, which will be situated on the Oudezijds Achterburgwal canal in the Dutch city’s red light district, is currently being printed in steel by 6-axis robots, which will “draw” the framework in the air.

At a ceremony to launch the project on Friday, Laarman told Dezeen that the task could usher in a new era of digital manufacturing.

“Everybody is speaking about 3D printing but not so significantly is really feasible however,” Laarman said. “We are making an attempt to lift the globe of digital fabrication to a higher degree.”

The bridge, which will be eight metres prolonged and four metres broad, will be printed in one piece in a former shipbuilding hangar in the Amsterdam’s NDSM shipyard and then transported to the city centre.

Function will begin subsequent summer time. Earlier plans to print the bridge in situ had to be abandoned as it was “just also unsafe”.

Laarman is unsure how extended the manufacturing procedure will get, despite the fact that completion is not expected before 2017. The style of the bridge will be finalised now that the place has been made the decision.

Associated story: Amsterdam architects plan 3D-printed canal house

“The bridge layout is a process that will consider some time,” Laarman stated. “Now we know the location we can commence functioning it out collectively with our partners.”

The Dutch designer has launched a new firm known as MX3D to build the technology employed to construct the bridge, which involves bringing programming robotic arms to handle welding machines.

“We’re proud to have MX3D in Amsterdam and we’re proud to have the 1st 3D-printed bridge in Amsterdam,” mentioned the city’s deputy mayor Kajsa Ollongren at the launch, before a robot wielding a golden pair of scissors cut a ribbon to mark the commence of the project.

The robots will construct up the structure by forming struts out of thousands of precisely placed blobs of molten steel.

The strategy can also be used to print with other metals this kind of as copper or aluminium.

“It opens up a complete new sort of 3D printing,” explained Laarman. “It’s about making robust but exclusive structural items.”

He added: “Printing with robots indicates you’re not limited any a lot more to the boundaries of the printer. Theoretically you can print infinitely big structures.”

Associated story: Joris Laarman Lab explores 3D-printed metal and open-source chair designs in New York exhibition

Salomé Galjaard, senior designer and project leader at Arup, mentioned the project represented a “genuinely big stage” for 3D printing of structures at an architectural scale.

“What’s wonderful about this undertaking is 1st that it really is infrastructure, which is possibly much more conservative than the constructing industry,” said Galjaard, who worked on a pioneering undertaking to print architectural elements in steel.

“It may get a couple of years nevertheless but we actually think that the bridge will execute,” she told Dezeen at Laarman’s launch. “It will be wonderful publicity for 3D printing.”

Laarman, 35, graduated from Style Academy Eindhoven in 2003. The bridge task builds on earlier research by the designer in how to print freeform structures in very first plastic and later steel. Ideas for the bridge have been initial announced in June this 12 months.

Below is the transcript of the interview with Laarman:

Marcus Fairs: Tell us what’s occurring right here nowadays.

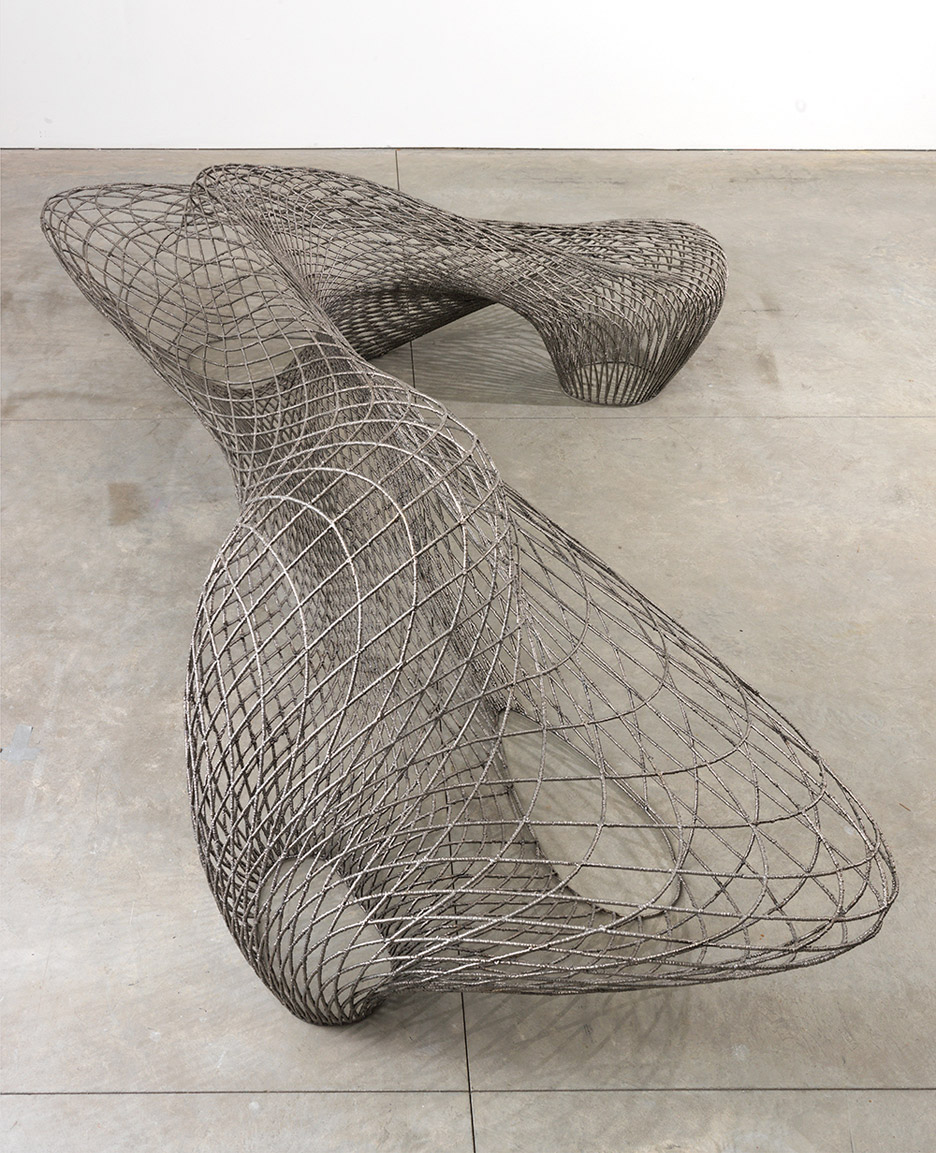

Joris Laarman: We’re opening the location where we’re going to develop the bridge. The robot is going to lower the ribbon and the deputy mayor of Amsterdam is going to reveal the place the place the bridge is going to be, which is in the city centre, in the red light district. At the back you see some experimental objects we have manufactured making use of the same method. They are known as Dragon Benches.

Marcus Fairs: Explain the technology you’ve developed.

Joris Laarman: The simple principle is super basic. It truly is a robot and a welding machine mixed. But the smart part of it is the software how we control the machine. What is great about it is that with wise software we can make an old machine extremely intelligent, make it do some thing sensible.

Marcus Fairs: Robots and welders are not new.

Joris Laarman: A robot is a really previous machine truly. It really is made to do a single point once more and again, one particular motion. It is created to pick and area. But by making use of wise software program we can make it move any way we want it doesn’t have to be a repetitive motion. It can do genuinely complex movements and it truly is in a position to communicate in true time with the welding machine. That’s what helps make it attainable.

Marcus Fairs: There has been a good deal of hype about 3D printing.

Joris Laarman: Digital fabrication is in its infancy. Everybody is speaking about 3D printing but not so a lot is truly achievable yet. We are making an attempt to lift the globe of digital fabrication to a greater degree.

Joris Laarman’s 3D-printed Dragon Benches have been made employing the same strategy that will be utilized for the bridge

Joris Laarman’s 3D-printed Dragon Benches have been made employing the same strategy that will be utilized for the bridge

Marcus Fairs: What does this engineering allow you to do that other sorts of 3D printing can not do?

Joris Laarman: Everyone of course is talking about 3D printing, but the great factor about steel is that it instantly turns into one thing that is genuinely functional. So you can really use it. The materials is very tough.

We have targeted on printing outside the box. Printing with robots signifies you are not constrained any a lot more to the boundaries of the printer. Theoretically you can print infinitely large structures. If the robot prints its personal track as it goes along you can print really huge-scale objects.

And it truly is printing in durable supplies, like steel or any other type of metal. It opens up a entire new type of 3D printing. It really is about producing strong but unique structural issues.

Practically almost everything you see around you seems to be the way it does since of the limits of industrial machines. With our technologies it makes it feasible to make much much more complicated or natural shapes. So it opens up a total new kind language. It also opens up the possibility to manufacture locally. So it doesn’t have to be produced in a factory on the other side of the planet.

Marcus Fairs: How did the bridge undertaking come about?

Joris Laarman: We were in San Francisco with Autodesk, our very first companion, and we had been brainstorming about what would be the ultimate poster undertaking for this technologies. We believed that a 3D-printed bridge more than a canal in Amsterdam would present all the facets of the technology.

I think it really is a genuinely lovely metaphor to connect 3D printing with the historic centre of Amsterdam. The design will get into account its place and will display the greatest of the two worlds, outdated and new.

Marcus Fairs: Initially you have been going to print the bridge in situ, but now you are going to do it in a warehouse. Why?

Joris Laarman: We genuinely wanted to print it at the actual spot but it’s just also harmful. It’s a single of the busiest places in Amsterdam. So it makes a lot much more sense to print it right here.

Marcus Fairs: In 1 piece?

Joris Laarman: Yes. Folks can come right here and visit.

Marcus Fairs: What are the dimensions?

Joris Laarman: It truly is about eight metres by 4 metres. It truly is not a massive bridge but we have to start off someplace.

Joris Laarman’s 3D-printed Dragon Benches had been proven in the Lab: Bits and Crafts exhibition in New York

Joris Laarman’s 3D-printed Dragon Benches had been proven in the Lab: Bits and Crafts exhibition in New York

-Marcus Fairs: How long will it get?

Joris Laarman: We will not know however! The style is a approach. We require to generate a framework that will consider everything into account, like its place in the city centre. This is also a approach that will take some time. The beauty of parametric modelling and digital fabrication is that we can make structures special for each and every spot, and so we will.

Marcus Fairs: You set up a new organization, MX3D, to develop the metal-printing technological innovation. How did that come about?

Joris Laarman: Following we figured out how to operate with these metal printers, we considered it was so promising that there was a complete globe of issues we can do with it. We desired to generate beautiful, big-scale furnishings pieces but there was not a tool around with which to do that. So we designed it ourselves.

Following a even though it didn’t make any sense any a lot more to preserve it in our small design studio. We needed to produce a whole company all around it. That is what became MX3D.

So now it really is a new startup business that is creating technologies. At the second we’re being approached by all kinds of organizations, like our new partners ArcelorMettal, which is providing the steel growth, Heijmans building company and Autodesk, who are working with us on the computer software. There is interest from offshore organizations. And we have been approached by different institutions concerning printing in area, for instance.

Marcus Fairs: What else could you do with the technological innovation?

Joris Laarman: The bridge is a really tough project. It will demonstrate us all the items we want to build over the up coming two or three years. So it truly is genuinely hard to say what we could make with it.

But you can make things that are exclusive. You can make customized-manufactured items that are distinctive, durable and huge scale. We can now commence 3D printing on construction sites for instance. There are so several attainable applications.